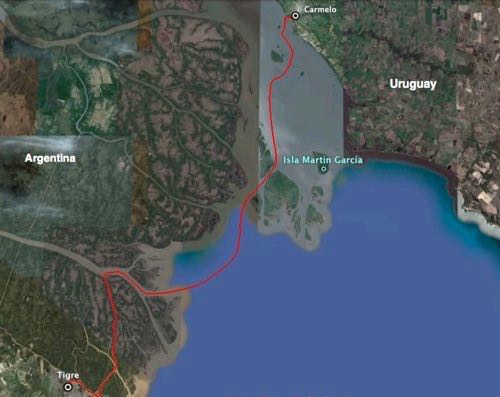

Tigre to Carmelo

They operate high speed catamarans and our route took us via Rio Lujan, Canal Vinculacion, Rio Urión, Rio Parana, Canal del Barca Grade, between Islas Lucia and Oyavide into the upper Rio de La Plata and on to Carmelo. Return Cost Arg$157 (£26.50) return.

Moorings along the bank of Arroyo de las Vacas in Carmelo. In another month or so these moorings will be packed with Argentine boats.

More empty moorings and the Hydrografica office.

Mooring is normally bow anchor down and stern to quay.

Bridge deck on our Cacciola catamaran.

Nancy on Avenida Wilson Ferreira near the ferry terminal.

Pedestrian route along Arroyo de las Vacas.

Interesting houses along the road to Playa Seré on the south side of Arroyo de las Vacas.

The skipper near Reserva de Fauna (didn't see any) on the road to Playa Seré.

Playa Seré

Entance to Carmelo harbour from Rio de la Plata.

Welcome to Carmelo.

Lunchtime refreshment. This is not locally controlled company. It is owned by the mega conglomerate ABInbev.

Playa Seré with Rio de la Plata beyond.

Hidrografia facilities adjacent to the yacht moorings.

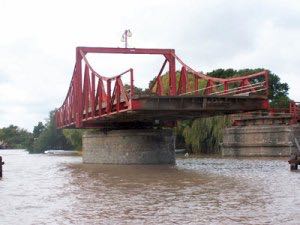

The first rotating bridge in Uruguay. Built in Germany and erected here in 1912.

We didn't see it open but this photo shows the bridge open to allow river traffic.

An old steam crane built by Grafton and Co of Bedford.

While looking around for some information about this company I found an interesting article on NZR Cranes.org. It is worth quoting.

Grafton & Co (Bedford)

Alexander Grafton (1845-1807) was articled in Paris before joining Appleby Bros. in 1867. He remained with the firm until 1879 during which time he spent 4 years in Egypt in charge of their work with the Sudan Railway and other contracts, and rising to assistant manager. He then spent more time in Paris before returning to London to set up his own firm, which was known from 1883 as Grafton &Co.

The company supplied a wide range of iron work including building framing, gasworks materials and locomotive spare parts, as well as contractors cranes, both hand and steam. Initially these were purchased in batches from Jessops of Leicester (later Jessop & Appleby Bros.) and resold either as standard or with customer specified extras. After Grafton entered partnership with C.Q.Henriques (a Frenchman) the company became an independent producer. The Vulcan Works were developed at a large site at Bedford with a LNWR connection in 1886.

Grafton had been granted a patent in 1882 for a loose race slewing gear with a conical seat. Patterning a new design on the Leicester produced 'Tilbury' crane included derricking and travelling functions (although these were later added by Jessops), and incorporating the patent slewing gear, this became the basis for what was known as the 'London' type crane. The crane had a short centre pin and horizontal engines, allowing a low centre of gravity. Brownlie notes that Grafton had the design perfected almost immediately and only minor details were added over time. The importance of this becomes clear when it is realised that manufacture continued into the 1960's.

The other important facet of the Grafton & Co. manufacturing was the use of standard sizing. At a time when many cranes were produced on a one off basis, Grafton produced five standard sizes in the 2 to 10 ton range. Castings were standardised and gearings were at standard centres, meaning only a few mechanical parts needed to be adjusted to suit customer requirements. Crane carriages were produced in a range of widths to meet gauge requirements. Any special contracts required little revision of drawing work and some extra machining. The foundry work was alsosystematic, with castings produced in batches and marked for model and size (very useful when spares were ordered). Because the company concentrated on sizes that were in demand it was able to keep one or two standard cranes in preparation allowing a fast response to customers. The company had also rigorously tested its cranes, noting engine and hoisting speeds for a variety of loads, derricking times and other useful details for customers, down to coal consumption.

Grafton cranes were put to a variety of uses. As well as industrial, many were used for docks and wharves, and there were also railway customers. The latter were primarily for permanent way work. As well as UK railways export markets included Scandinavia and Argentina. One crane is known to have come to New Zealand, being imported by the New Zealand Midland Railway.

After Alexander Grafton's death in 1907, control of the company passed to his nephews. Although some development work continued (using new materials such as phospher-bronze and steel changing from chain to wire rope, and converting to new power units) business began to reduce in the post WWII period as railway and shipping demands changed. The company had little business after 1960, and follwing the death of one of the nephews in 1963 dissent amongst the family saw the Vulcan Works close. The assets and goodwill of the company was transferred to Taylor & Hubbard who maintained a parts service for Grafton cranes. The UK's Historical Manuscripts Commission holds records for Taylor & Hubbard up to 1981, but I do not know what has become of the company since.

Other examples of Grafton products in South America can be found here.

Uruguayan flag on an our Cacciola ferry.

Returning via Canal Vinculacion work was in progress on a very large new housing/mooring development.

Along the Rio Lujan old ships are not scrapped. They are run into the bank and allowed to rust away (slowly). .

.

Prefectura Z28 Class WPB Patrol Boat "Madryn" based in Tigre. Built by Blohm & Voss 20 of these boats entered service in Argentina between 1979 and 1980.

A Tigre built Cacciola catamaran ferry of the type we were travelling on.

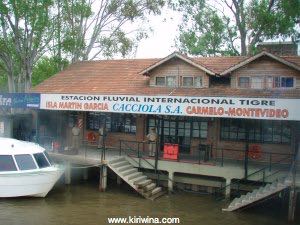

The international ferry terminal at Tigre.

With very, very careful attention to water levels it would be possible for Kiriwina to do this trip.